To err is human is a cliché which has been flogged to death, however what is important for organizations is to realize this fact and act on it. If to err is human, to realize this fact and to act on it is the role of management in this era of globalization.

Poka Yoke:

For an operator to perform an operation with zero error day in and day out is difficult. Errors are bound to happen; so what is important is to ensure how processes and systems can prevent such errors from happening.

This is where the concept of Poka Yoke or Error Proofing comes in. The idea is to prevent defects from occurring or to prevent the errors to lead to defects. It is important for us to understand the difference between errors and defects.

Errors and Defects

Errors are the causes for defects and defects are the results. The primary focus should be to prevent errors from occurring, or at least detect errors and defects that have occurred. When we talk of zero defects, what comes to my mind is error proofing. I don’t think there is any better way to achieve zero defects and for sure there is nothing better than zero defects.

Shigeo Shingo

To drive this point further, I would like to quote Shigeo Shingo, who said “It took 26 years from my first encounter with SQC systems before I finally arrived at the notion of a Zero QC system. In retrospect, I cannot help but marvel at how thoroughly I had been under the spell of statistics. I can only feel that I had been so taken by the magic of statistical methods that I had forgotten to pursue the nature of quality control itself. Only when I happened on the poka-yoke idea and the notion of trouble-free 100% inspections did I realize that one did not have to use statistics. Not until then did a chink appear in the wall of statistics. That hole gradually widened as the implementation of 100% inspections and rapid feedback and action cut defects dramatically. At that point, I looked into the nature of quality control and arrived at the idea of Zero QC system. This is what first made possible the attainment of zero defect.”

Poke Yoke was originally developed in the 1960s by Shigeo Shingo in Japan

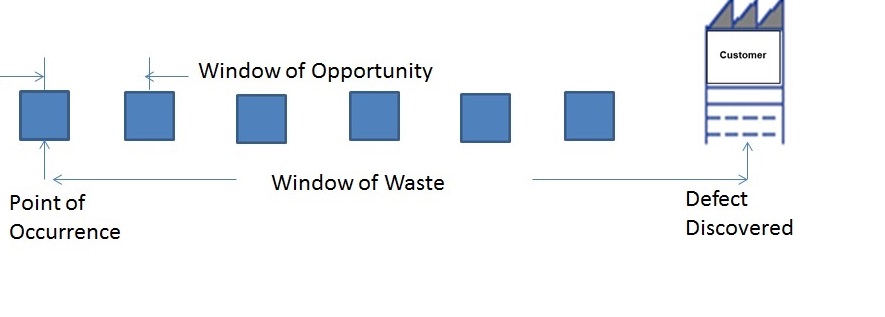

Source Inspection and Window of Waste

Source inspection is used at the error stage, to prevent errors from turning into defects. The focus is on preventing the error from becoming a defect. If it’s not possible to prevent the error, then we at least want to be able to detect the error.

Inspection carried out farther away from the source is a waste. The time and distance between the point at which the error occurred and the defect was observed is known as the “Window of Waste” relative to that defect. There is always a “Window of Opportunity” between the error prone condition where the error could have been discovered preventing the defect downstream in the process flow or at the customer’s end. Forgetting to turn the headlights before exiting the vehicle is an example of error prone condition. By shortening my window of waste through the detection of an error early in the process, I can possibly avoid the defect (dead battery).

Examples

There are several examples of error proofing .Look at all the connectors that can go into a lap top, there is no way of putting a wrong connector into any of the sockets. There are some suitcases which cannot be opened if placed upside down. Circuit breakers prevent overload and when the load exceeds the limit the circuit is broken. Washing machine doors cannot be opened when the machine is running, or the machine stops if we open the door. There are of course so many examples that have been implemented to take care of safety of users of equipment. We also see this in web application, wherein missing data or in appropriate city name, date of birth or other incorrect details may be prevented.

This is indeed a very easy concept to understand, with some thinking and brain storming sessions, teams can explore opportunities in their respective work places. The key motive should be to prevent an error. If that’s not possible, at least prevent the error that leads to defect; or at least have systems to detect the defect at an early stage and do not allow customer to detect it.

Well to err is human, but to prevent errors and prevent errors that lead to defects is definitely possible by using engineering knowledge and techniques.

Pradeep Kumar ET

When my dad and I were discussing about what to name our factory “ZERO ERROR COMPONENTS” or “ZERO DEFECT COMPONENTS”

It was then my dad explained that even though there was a minute error (within tolerance limit) in the components there wouldn’t be defect in the functioning.

We had to maintain accuracy of two thousandth of a millimeter.

We decided to go with :

ZERO DEFECT COMPONENTS