Is there a day you went out of your house and didn’t see any repair or rework being carried out or something waiting to being mended or repaired?

The Repair Mindset

Isn’t it sad to see things always falling apart and reworking becoming an acceptable practice; may be in the city you live or the place you work? A mason or carpenter or any worker knows for sure that if things go wrong, there is a way to fix it. He also knows that it would be tolerated and accepted by the user or the customer, as long as the defect is fixed. “First time Right” apparently is not a term known to many, though we see many organizations using this term in their Quality Policy.

Most of us have the experience of supervising the construction of our home or the new flat we intend to buy; rework I think is rampant here. The carpenter or electrician or the mason would without the slightest concern, mess up the newly laid flooring. However getting upset about it is considered absurd, because everyone knows that at the end, they would do a ceremonial “Acid Wash” on the floor.

People who supervise and carryout rework are rarely concerned about the harm that rework does to the environment and the surroundings. An acid wash could actually cause damage to the cementing of the tiles in the long run. The repair on the roads cause damage to the pavements or the repair on the median can cause obstruction to traffic and also lead to accidents. A product which is repaired can never be considered original or brand new; like a repainted car looses its market value. So I think in the first instance, as customers of products and services we must demand products to be done right first time and prevent rework. Recently I had the bad experience of buying a high end business laptop which was defective and I insisted that the product be taken back and not repaired, as reworking would be like buying a refurbished laptop. Unfortunately the second laptop, which had the next generation processor, had the same problem and I promptly returned it.

Rework impacts Productivity

The option of rework is what makes the entire system inefficient; though the irony is that things are done fast to meet schedules, with the intention that in case anything goes wrong, it can always be reworked.

To the question, “Why productivity increases as quality improves?” Dr. Deming’s answer is simple and straight forward, “Less rework”. So if we have to improve both quality and productivity, our society must get tough on people who live on the philosophy of rework. It’s a big change that has to take place in our country. All of us have to change- starting from the mason, the carpenter, the gold smith, the tailor, the road building laborer, the machine operator and the concerned supervisors and engineers.

First Pass Yield

Though, the change is expected to happen at the bottom of the heap i.e. the people who actually carry out the operations; the change in mind set and thinking has to happen at the management level of the enterprise, and this is applicable to both, private companies or government bodies.

For organizations to really start focusing on this issue, the first step, probably, would be to start capturing the right data. Like in companies that practice Operational Excellence, when they talk of defects, they are actually looking at parts that did not come okay at the first pass. If we say a product has a 500 ppm defective, it doesn’t mean that 500 parts in a million are scrapped, it could mean that 500 parts (or equivalent proportion) was accepted under deviation or after rework. This metric, with a focus on ppm reduction, brings continuous pressure on reducing not just defects, but also rework.

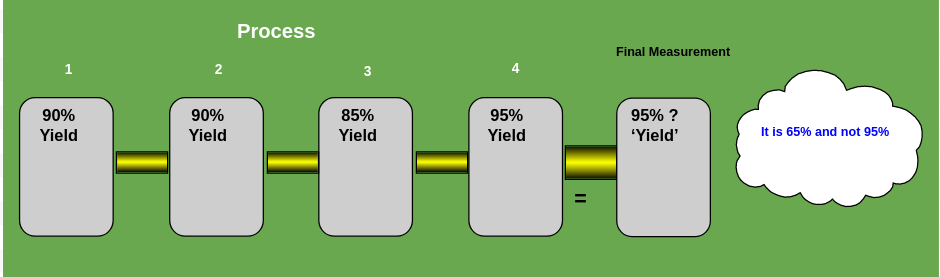

Rolled Throughput Yield

Well, looking at the yield only at the final inspection stage hides the true process yield. The true yield, called the rolled through put yield is the product of the yield at each stage of the process.

In the figure above it would be wrong to just look at the yield at the final stage. We will have to look at the yield at each stage and take the product of all stages; so the rolled through put yield would be 65% and not 95%. (90%x90%x85%x95%) This is a clear indication of the reduction of productivity due to quality issues.

One of the principles of Toyota Production System is “Build a Culture of Stopping to Fix Problems, to Get Quality Right the First Time”. Taiichi Ohno , who developed the Toyota Production System said, “No problem discovered when stopping the line should wait longer than tomorrow morning to be fixed”. Not fixing it will cause defectives to be passed down the production line to the other stages, creating pile of rework and inventory and also they know for sure that they will have the same problem again tomorrow.

The first task though is to prevent problems from occurring, but if a problem still occurs, we must make sure that the root cause is addressed so that it doesn’t recur. This will ensure that rework quantities do not pile up and affect process flow, inventory, quality and productivity. So it’s just not “Wage war on Waste”, its “Wage war on the philosophy of rework”.

Thanks. Enlightening and reinforcing article👏👏👏

Excellent Topic and Thought provoking . This applies to Software Industry also where lot of Budget gets burnt in creating a Stable system which can cater to what actually a customer needs . If we make the cost of rework higher than cost of product then may be this culture would go away , Carpenter or Technician should get the same Salary as an engineer which obviously would make the repair cost high then cost of the Product .